Pride of Stax

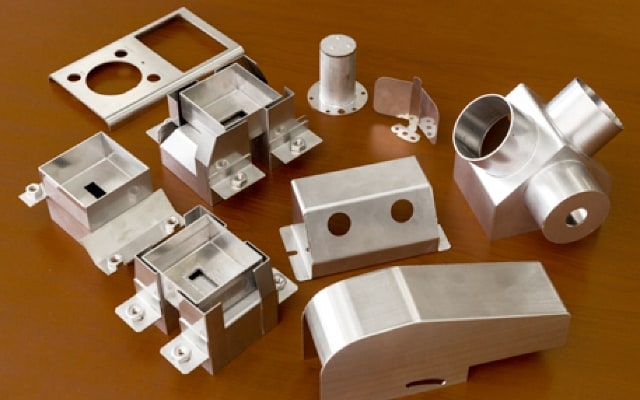

Stax is engaged in precision sheet metal processing and aluminum welding of materials Stax received from customers, such as enclosures of aerospace instruments, of automotive sheet metal welders, and of equipment for the Self-Defense Forces and medical use, brackets for communications equipment, parts for the H-II (H2) rocket, and machine control panels, as well as manufacturing and sale of its own products.

We has satisfied more than 1,000 companies in 50 industries since its establishment, not only by providing technology related to precision sheet metal processing and aluminum welding, but also by meeting myriads of customer needs associated with metal processing.

Specializing in precision processing of sheet metal (0.01 to 0.3 mm thick)

Stax is proud of its core technique of precision processing of sheet metal as thin as 0.01 mm. Stable and high-quality processing is essential for satellite parts and medical equipment enclosures. Stax’s track records show that it has been highly trusted by customers for more than 20 years. We believe that our improved technique of precision sheet metal processing enhances the performance of customers’ products. Stax’s strength is its highly skilled craftspeople who can perform high-precision finishing by hand, which machines cannot achieve.

Stax’s services covering from consultation based on rough sketches to CAD drawings

Our in-house design engineers prepare design drawings from customers' rough sketches, allowing Stax to do everything concerning manufacturing, from precision sheet metal processing of thin sheet metal of 0.1 mm or less thickness to the production of well-designed enclosures without outsourcing. Stax has many partner companies with specialized expertise, so painting and plating are also available through Stax.

No minimum order quantity

Stax, specializing in high-mix, low-volume production, is willing to manufacture an item “whose production quantity is just 1 and which is not subject to repeat orders.”

We also owns a variety of equipment, so as to provide anything from prototypes to production of about 50 pcs of enclosures.

Traceability of materials and production processes

Before the final inspection, Stax conducts in-process inspection and shipping inspection at each production base. Stax also offers services to store inspection records, report actual values, and manage various certificates.

Processing where the variation of multiple same parts must be minimized is Stax’s speciality. By aligning the rolling directions of the sheet metals used for the part, the variation of the part due to the material can be reduced as much as possible.

We hold a quality meeting every month. All of Stax’s craftspeople exchange information on problems and improvements in their work processes at the end of each month.

We provide mill sheet in PDF format free of charge upon request.

Stax values communication with customers

Through close communication with customers, Stax’s sales representatives understand the customers’ needs that drawings cannot indicate, and give detailed processing information to Stax’s craftspeople in the factory. Accordingly, they can smoothly reflect customers’ needs in the products. For first-time customers and first-time orders, even if there is only one order item, upon a request from the customer, Stax will make a prototype of the requested item and obtain the customer’s confirmation before starting production or processing.

Safe and reliable delivery of your orders

Stax offers special packaging to meet a request to deliver products without scratches. Precision is vital for processed thin sheet metal in particular. To prevent products from being deformed in transit, they are carefully packed with sufficient pads and silica gel desiccant so that they are preserved as they were finished.

Stax uses its own jigs

For optimal processing and assembly, Stax’s craftspeople build their own jigs by themselves. Stax bears the cost of developing jigs.

Stax’s ISO 14000 certified factories

Since acquiring ISO 14000 in November 2004, Stax has been increasing its environmental awareness. Twice a year, Stax conducts internal ISO 14000 audits, with the head and the next ranked employee of each department who serve as the leader and the sub-leader, respectively. All of our corrective actions are reported to the president once a year, and the report is posted in each department to ensure that all employees are aware of them.

Stax is responsible for any defects in its products on a top-priority basis

As soon as a sales representative receives information about a defective product, the representative promptly reports it to the president and the head of the production base related to the defect, who make the information known to all concerned. If a defective product is returned to Stax, an investigation report on it will be given to the customer as soon as possible. If the same product is in stock, Stax will ship a replacement immediately.

Supply chain risk management

Stax has three production bases, which contributes to reduction of production risks. In addition to reducing risks by decentralizing Stax production bases, Stax has a system that allows its factory staff to conduct any process. Stax’s in-house developed production management program offers optimal production methods to customers. In addition, any of its production bases can check the production progress and delivery status of the others.

Our services

With our specialty in high-mix, low-volume production, we are able to make our customers expand their product variations with the latest fiber laser cutting and special radius bending that can be applied to copper, brass, and aluminum.

YAG laser welding

YAG laser enables to weld very thin sheet metals (0.3 mm to 0.5 mm) with minimized distortion and excellent welding finish.

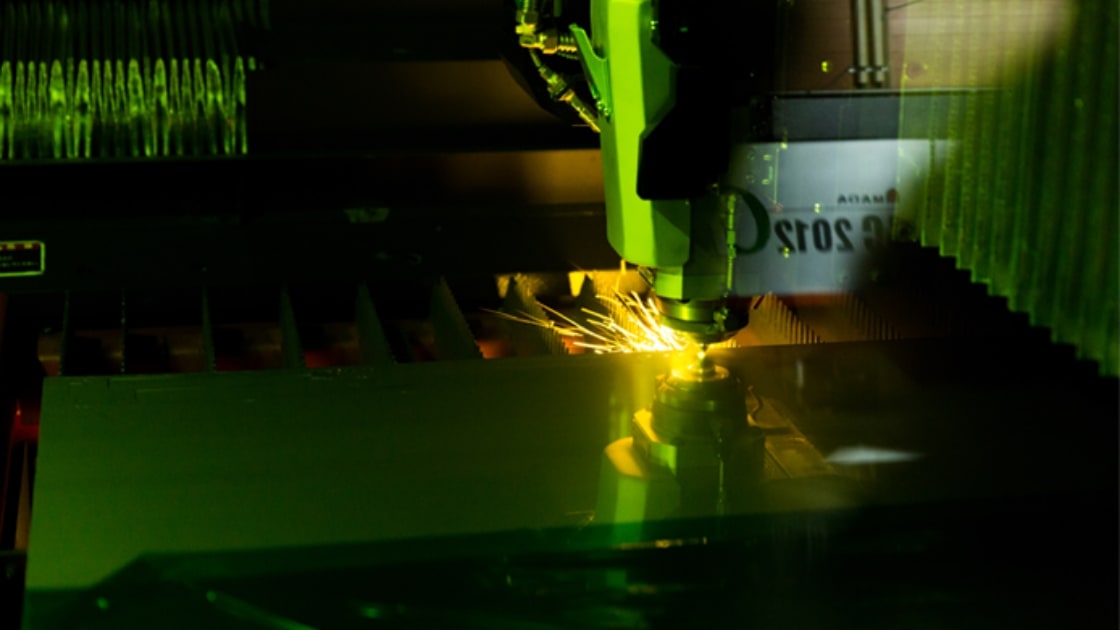

Fiber laser cutting

Fiber laser enables to cut highly reflective materials even with a thickness of 0.1 mm. We offer this service starting from 1 pc.

This laser can cut products with complex shapes in a short period of time.

Blanking

Our leading-edge fiber laser cutting machine enables us to laser cut highly reflective materials (copper, brass, and aluminum).

The minimum plate thickness for blanking is 0.1 mm, and we have proven results in electrode manufacturing.

With the three-axis linear drive installed in the cutting machine, we can now cut products that require high precision (tolerance in the hundredths) than ever before. We offer this service starting from 1 pc.

Welding and finishing

From thin sheet metals and small parts to enclosures, Stax’s weld finishing is “weld-done.”

If you are craving for enclosures with clean appearance, we would like to hear your desired finish to make you satisfy.

Stax has a great deal of experience in TIG welding the exteriors of well-designed enclosures for medical devices and other products, and we are particularly good at welding products that require precision and aesthetics.

With the YAG laser welder we have, we are confident that we can weld thin sheet metal with no distortion.

Deburring

We can deburr workpieces as small as 0.1 mm by hand finishing.

Bending

Even if you have a request for special radius bending, Stax does not require any extra investment for dedicated metal molds.

In the bending of thin sheet metal, an aluminum sheet metal with a thickness of 0.1 mm can be bent if the desired workpiece can fit in your palm.

Main equipment

| Equipment name | Performance | Number of unit |

|---|---|---|

| FLC-2412AJ:Fiberlaser cutting machine | Can blank highly reflective materials | 1 |

| PEGA345NC:NC Thick turretpunch press | 30t | 2 |

| EM-255NNC:NC Thick turretpunch press | 20t 1270l 2500 | 1 |

| LC2012CN1NT:Punching laser composite machine | 20t 2500w | 1 |

| DWC90H:Wire cut system | T50-100 w200l D250 | 2 |

| RC80:Hydraulic press brake | 80 tw 2000 | 1 |

| RC50:Hydraulic press brake | 50 tw 2000 | 1 |

| RC30:Hydraulic press brake | 30 tw 2000 | 3 |

| RC25:Hydraulic press brake | 25 tw 2000 | 1 |

| FBDIII-1025NT:Hydraulic press brake | 100 tw 2500 | 1 |

| HDSNT8025:Hydraulic press brake | 80 tw 2600 | 1 |

| Condenser spotwelder | 40500F 475V | 1 |

| Condenser spotwelder | 1500WS | 1 |

| Inverter spotwelder | ID-40IV HP | 1 |

| YAG laser welder | SUS 1.5mm | 1 |

| Table spotwelder | SPCC 2.3 | 1 |

| CTS900NT:Network NC Tapping Machine | 1 | |

| SD600:NC stud welder | 1 | |

| ECP-500:Automatic caulking machine | 1 | |

| VHD-G:Vertical/horizontal compositemillingmachine | 1100l 2800mm | 1 |

Results

- Enclosures,Water filtering apparatus,Blood analyzing device,Landslide inspection apparatus,

- Edible oil regeneration device,Card payment machine,Automotive sheet metal welder,

- Storage box for Japan’s Self-Defense Force,Low frequency massager (for medical use),

- Food inspection device,Machinery,Parts for artificial satellite for planet probe,

- Mounting brackets, fittings, chassis for communication equipment,

- Parts used in the H-II rocket,Machinery parts for machining equipment,

- Heat radiation plate with multiple holes (heat sink),

- Machinery parts for digital printers for business use,

- Machine control panel,Machinery parts for exposure equipment,

- Machinery parts for large washing machine

Delivery process

-

Your inquiry (By email or from our website)

-

We hear from you the details of your idea

※Provide us a drawing (a rough sketch is fine) if appropriate

-

Design/drawing

-

You check the made drawing and give us the green light

-

Quotation

(depending on the scale and difficulty of the work, the delivery of the product will take one to seven days)

-

Prototyping

(we make a prototype of the product upon request; intermediate inspection is also available)

-

Fabrication

(Blanking, deburring, bending, and welding; each process includes quality checking)

-

Final quality inspection

(we submit inspection warranty upon request)

-

Delivery

Transaction conditions

If a non-disclosure agreement shall be signed, please let us know in advance;we will provide you with our format.*Using another format may require more time to conclude the contract.Please make a bank transfer to our bank account, which is provided in the quotation, within 3 business days after you approve the quotation,We will start fabrication after the payment is confirmed. So, please consider the lead time of payment.The payment method we can accept is international money transfer or PayPal.Please pay for all fees related to the payment of charges.The supported currencies are Japanese yen and U.S. dollars;

please let us know in advance which currency you wish to trade in.We will not issue evidence of your payment.Instead we will use your remittance documents as evidence of your payment.Please let us know the person in charge and his/her email address upon payment, so we can send an email to him/her once we confirmed the payment.

About our company

| Company name | Stax |

|---|---|

| Founded | In March 1, 1993 |

| Established | In November 25,1953 |

| The name of the company chenged | In April 1, 1992 (former name:Daisei Industry inc.) |

| Capital | 33,000,000 JPY |

| Founder | Shigeo Hoshino |

| Chairperson | Kiyoko Hoshino |

| President | Yoshifumi Hoshino |

| Headquarters | 1750 shimonumadbe, Nakahara Ward, Kawasaki, Kanagawa |

| Phone Number | +81-44-433-1611 |

| Fax Number | +81-44-433-2218 |

| Stax Katsuura office | 85-1 Nagi, Katsuura, Chiba |

|---|---|

| Phone Number | +81-47-076-3115 |

| Fax Number | +81-47-076-3116 |

| Stax Tokamachi office | 60 Tei, Tokamachi, Niigata |

|---|---|

| Phone Number | +81-25-761-7731 |

| Fax Number | +81-25-761-7741 |